Care & Craft

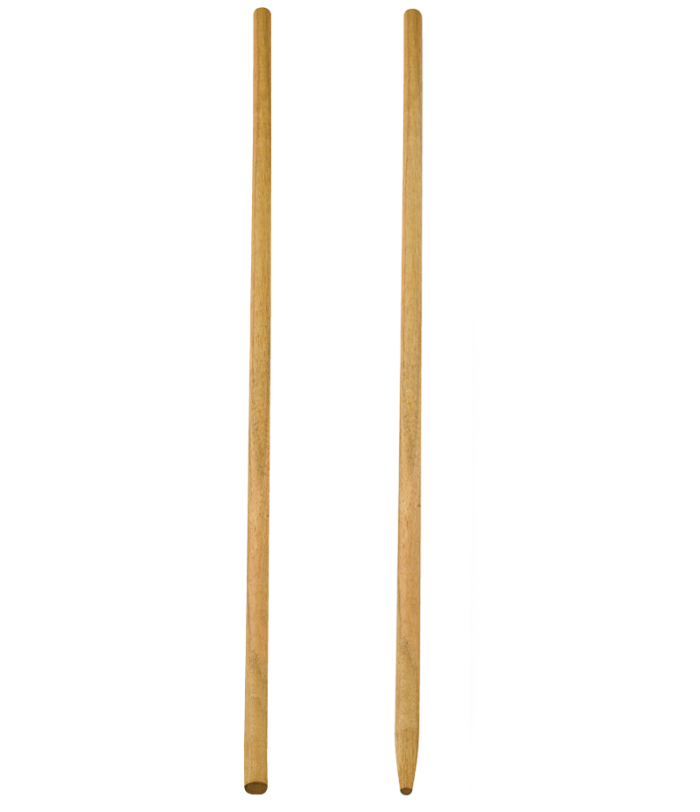

To us, a handle is more than just a piece of wood. Each handle is carefully selected from straight grained hardwood, graded by hand and an experts eye, ensuring only the best handles are fitted to all Carter’s Approved tools.

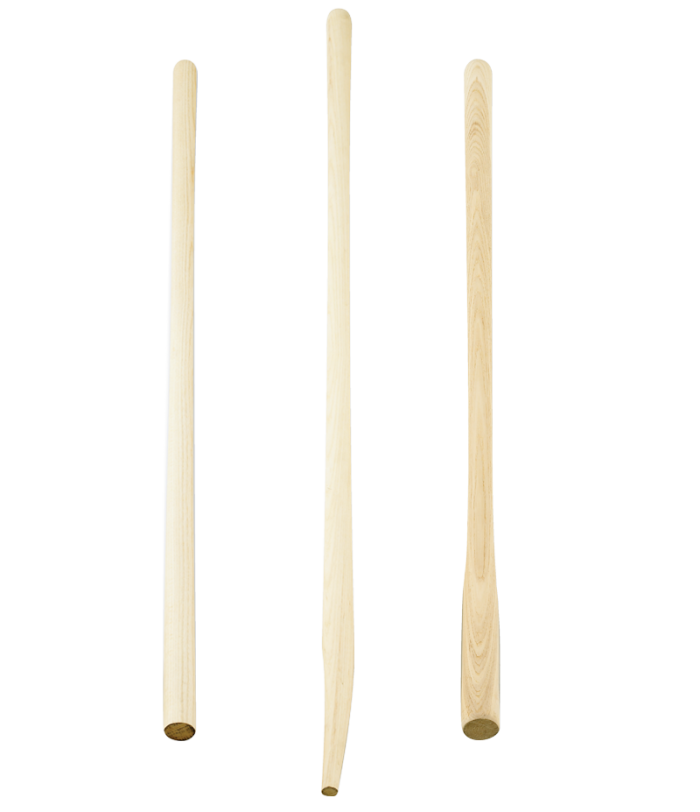

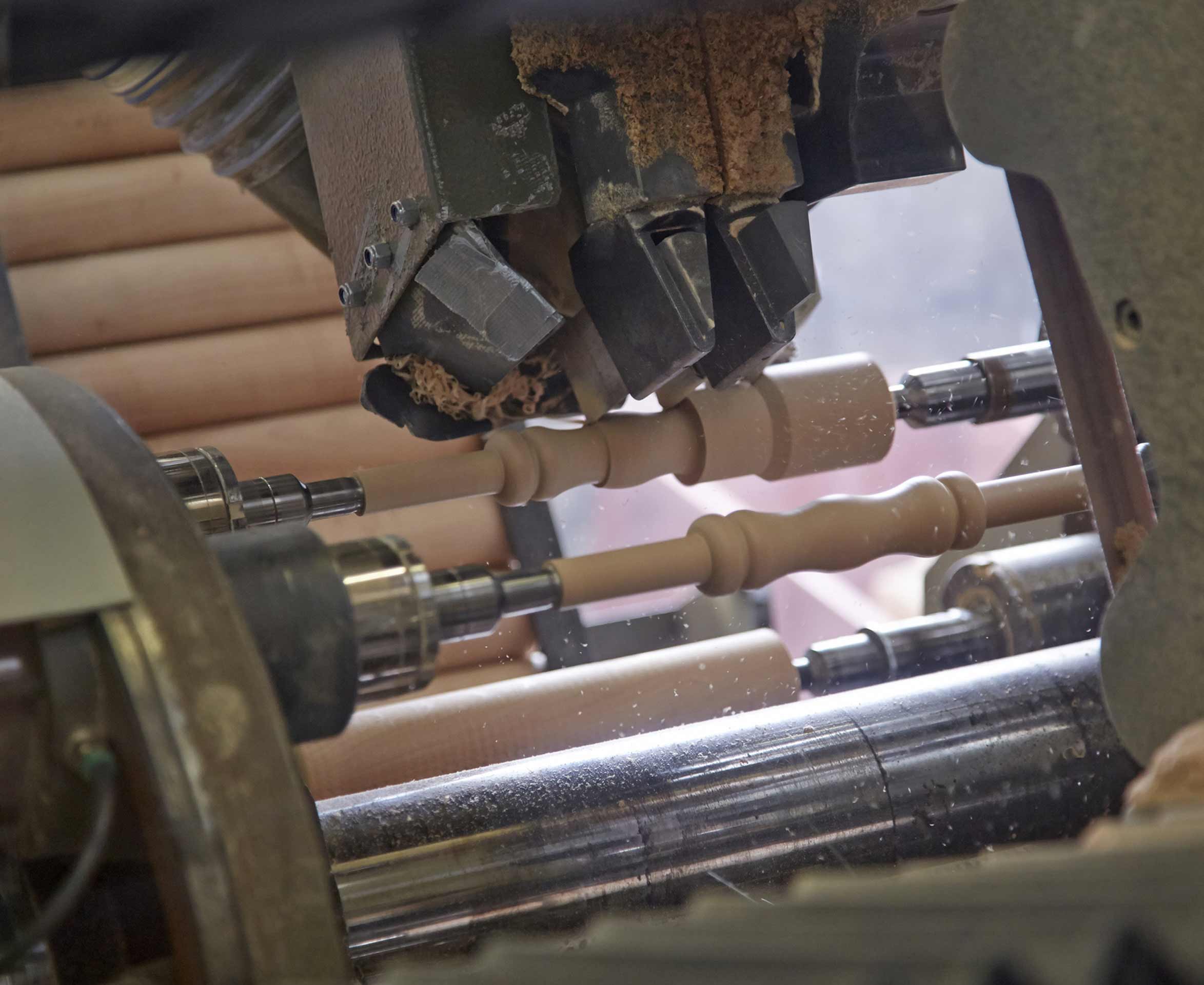

Manufactured, at our Huddersfield woodturning facility from the finest hickory, ash and hardwood timbers, selected for uniformity and straightness of grain and ergonomically designed to reduce vibration in use, our handles are available in a variety of lengths, shapes and sizes.

Did you know we provide replacement handles too?

Sometimes our handles need to be replaced, as they are in constant use over a number of years so can become uncomfortable to use. If you let us know the make/model you have, we can simply organise to replace the handle for you.

All in

the details