Click to view...

Wood YD

This 'Y' or 'D' handle is made from a single piece of high quality ash and is primarily used within our garden range. All our Wood YD handles are lacquered as standard to give a traditonal feel.

Ergonomic PYD

Moulded from a high impact polypropylene for increased comfort, the Ergonomic PYD helps to reduce strain on the hand and wrist by keeping the hand in a natural position whilst in use.

Shaped Long Shafts

Solid timber handle, designed to give a longer reach on a tool, so that the user does not have to bend. The wooden handle has a 'waisted' diameter for easier manipulation and a 'knobbed' end.

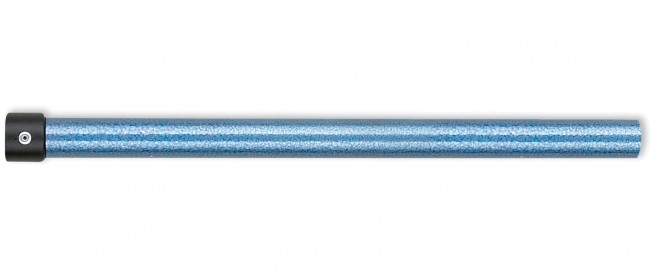

Tubular Plain Grip

This shaft is for heavy duty industrial work for digging or lifting material out of trenches - giving a much longer reach for the more arduos tasks. Manufactured in steel

BS8020 Shocksafe Insulated

Shocksafe products provide full conformity to the exacting specifications of BS8020:2011. Double protection created by twin layers of sealed polymer sheathing moulded over the rigid fibreglass core. Uniquely numbered and individually certified providing full traceability, guaranteeing full conformity to live-cable working specifications.

FibreMax Pro

The fibreglass MYD handle is designed for extremely heavy duty industrial use. Chemically bonded into solid socket tools, these shafts are over 30% stronger than 'All Metal' types. Fibreglass shafts have excellent structural properties and will not warp or rust in extreme weather conditions.

Polyfibre Pro

The Polyfibre style of handle is designed to offer the workman a high degree of fibreglass strength along with the comfort of a profile moulded PYD hand grip. The pultured fibreglass core is coated with an injection moulded polypropylene sheathing creating strength and stability.

Tubular All Steel MYD

This type of handle is mainly used for Contractors and Heavy Industrial Tools. We weld our steel handles into the body of the shovel socket for extra strength and rigidity, producing a very strong and robust tool for digging.

Metal MYD

This metal YD grip is mainly used for Contractors and Heavy Industrial Tools. Manufactured from a tough steel frame and fitted with a robust wooden hilt and rivetted to resist twisting. Extremely strong and can be fitted to wood, aluminium, steel or fibreglass shafts.

Polyropylene YD

This 'Y' or 'D' shaped grip is moulded to comfortably fit the hand, from high impact polypropylene. Normally fitted to wooden, aluminium or tubular shafts it is totally weatherproof and easily kept clean.

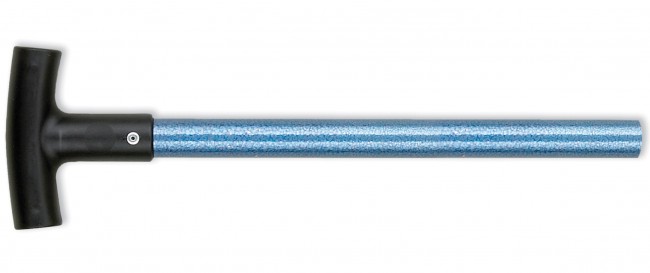

Polypropylene T-Grip

This high impact moulded polypropylene T-Grip is normally fitted to lightweight tubular products. Contoured into a non-slip grip, it is easily kept clean and is totally weatherproof.

Shaped Crutch T

This is a traditional Ash T-Grip, having a sculptured hilt, ergononmically shaped to fit the palm of the hand. The grip and shaft are mortised, tenoned and waterproof glued into place. A wooden dowel then secures the grip firmly into place.

Barrel Crutch

This is a plainer and more economical type of T-Grip. The handle top is not as intricately contoured as the shaped grip, but being mortised, tenoned and glued, it does possess all the same strength characteristics.

Solid Socket

Solid socket tools have their blades and sockets hot, double roll formed from one single piece of best quality steel. The socket is forged as an integral part of the blade (with NO welds) and this type of tool is readily identified by the fact that the handle fits into a 'blind' socket - this is the most popular range. Solid socket tools are prefered for heavy shovelling out, or back-filling trenches, mixing concrete, tarmac and ballast work. A range of handles are available in wood, steel, aluminium and fibreglass.

Open Socket

Open socket shovels are used for moving loose earth, sand, gravel and grain etc. They are hot-pressed from pre-cut sheets of either hot rolled heavy gauge Carbon Steel or Aluminium sheet. They are not primarily designed for digging or levering. This type of shovel is easily identified as Open Socket by the fact that the end of the handle (normally wood) can be seen protruding through the bottom of the pressed socket.